Industry 4.0’s Digital Twins: Smart Optimization or Surveillance in Disguise?

The Rise of Industry 4.0’s Digital Twins

The fourth industrial revolution Industry 4.0 is embedded in the fabric of modern manufacturing. At its core lies a transformative force: digital twins. These real-time, data-driven virtual replicas are being heralded as game-changers, offering unmatched efficiency, automation, and predictive power. But with their rise, a darker narrative is emerging one of ubiquitous surveillance and algorithmic oversight. The same technologies that promise optimization are also redefining workplace transparency, often at the cost of personal privacy.

Layered with augmented reality elements, digital twins allow managers to monitor equipment, processes, and more controversial people. The augmented reality meta isn’t just visualization; it’s control. And as enterprises rush to digitize every aspect of their operations, the question becomes urgent: Are digital twins tools of innovation, or subtle instruments of domination? In a world shaped by smart factories and real-time simulations, the line between productivity and control has never been thinner.

What Are Digital Twins in Industry 4.0?

The Backbone of Smart Manufacturing

Digital twins are not mere simulations; they are dynamic, continuously updated virtual replicas of physical assets. In Industry 4.0, they serve as the nervous system of smart factories, collecting and analyzing sensor data to mirror every aspect of production. From equipment behavior to energy usage, digital twins generate actionable insights that reduce downtime and improve quality. They are embedded in systems where predictive maintenance and AI-driven analytics are standard.

Beyond Replication: Data-Rich, Self-Learning Ecosystems

What distinguishes a true Industry 4.0 digital twin is its ability to evolve. These systems don’t just mirror; they learn, adapt, and optimize in real time. When paired with augmented reality meta, operators and managers can interact with complex data layers visually, overlaying simulation feedback directly onto physical equipment. This fusion of real and virtual creates data-rich ecosystems that adapt autonomously, challenging traditional hierarchies of control.

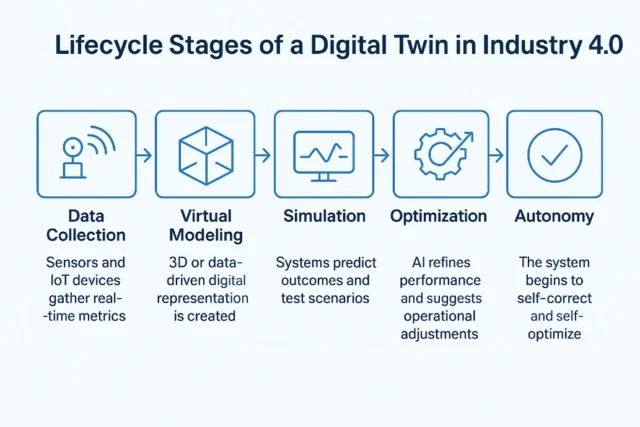

Lifecycle Stages of a Digital Twin in Industry 4.0

The Case for Smart Optimization with Digital Twins in Industry 4.0

Efficiency, Cost Savings, and Operational Uptime

Digital twins deliver real business value. Companies deploying these systems consistently report reductions in downtime, faster production cycles, and substantial cost savings. In logistics, predictive routing improves fleet efficiency. In energy, grid simulations prevent blackouts. These are operational realities. According to McKinsey, organizations that have adopted digital twins in full capacity have seen a 10%–25% increase in efficiency metrics across key operations.

Integrating Augmented Reality Elements to Enhance Monitoring

Augmented reality elements now elevate the digital twin from an analytics tool to an immersive operational dashboard. Engineers wearing AR headsets can “see” temperature spikes, vibration anomalies, and maintenance alerts overlaid on physical assets. In the augmented reality zone, every valve, motor, and circuit board is layered with live telemetry. This turns complex industrial environments into interactive decision interfaces, radically accelerating time-to-action.

ROI Comparisons Across Industries Using Digital Twins with AR

| Industry | Avg. ROI (%) | Use Case Example |

| Manufacturing | 22% | Predictive maintenance and quality control |

| Energy | 18% | Grid load balancing and fault detection |

| Logistics | 16% | Fleet routing and supply chain visibility |

| Aerospace | 25% | Component testing and system simulation |

The Surveillance Argument: Are Digital Twins Going Too Far?

Total Data Visibility or Total Worker Monitoring?

Where does optimization end and surveillance begin? In modern factories, digital twins track not only machines but also human workers. Every step, gesture, and pause can be recorded, analyzed, and evaluated. Proponents call this transparency; critics call it techno-authoritarianism. The system identifies inefficiencies and assigns responsibility. According to Harvard Business Review, such data can enable hyper-performance cultures that verge on digital Taylorism.

The Augmented Reality Zone of Control

The augmented reality zone is becoming a behavioral management tool. Workers guided by AR glasses are prompted, corrected, and even paced. The same AR that empowers technicians to detect faults also enables supervisors to monitor micro-behaviors. What happens when the workplace becomes a training ground not just for machines, but for docile, data-perfect workers?

Digital Twin Surveillance Capabilities

- Real-time location tracking

- Productivity scoring per task

- Behavioral nudging via AR prompts

- Fatigue and attention span analysis

- Unauthorized area entry detection

Digital Twins and the Ethics of Control

Algorithmic Management vs Human Autonomy

The rise of algorithmic management where data, not humans, dictate decisions, reframes traditional management ethics. Digital twins remove subjectivity, but they also remove discretion. When performance reviews are replaced by dashboards, the human layer vanishes. Autonomy becomes a variable in a control system. Tech measure and enforces!

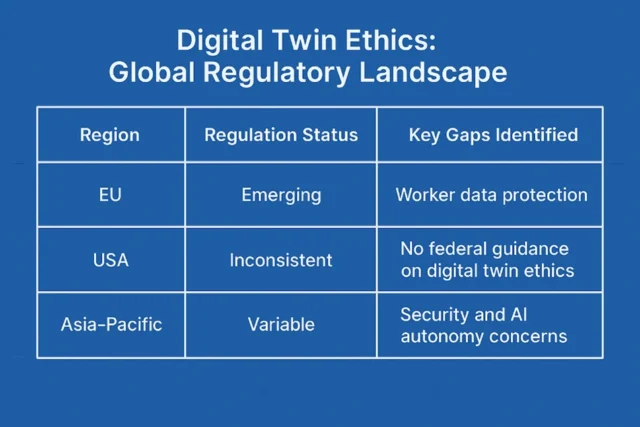

Can Regulation Keep Up With Innovation?

Legislation is consistently a step behind. While the World Economic Forum calls for ethical AI in industrial contexts, current global frameworks are patchy at best. Few jurisdictions have specific rules on data rights in digital twin systems. The pace of technological advancement outstrips institutional preparedness leaving regulation reactive and fragmented.

Regulatory Gaps on Digital Twin Usage

The Power of Augmented Reality Meta in Industry 4.0

Creating Immersive, High-Fidelity Simulation Environments

The augmented reality meta is redefining simulation. High-fidelity virtual environments now mimic real-world physics, conditions, and outcomes. Teams can test scenarios from safety protocols to process changes without disrupting operations. Training modules become lifelike. Maintenance rehearsals become mistake-proof. This shift from theory to immersion minimizes risk while maximizing readiness.

From Visualization to Immersion: Changing the Factory Floor

The factory floor is now an interface. AR tools immerse users in data. Decision-makers navigate heat maps, performance overlays, and risk indicators through intuitive visuals. This immersive design speeds up comprehension, improves safety, and democratizes data understanding across roles.

AR Technologies by Function in Industry 4.0

| AR Tech Type | Primary Function | Industry Use Case |

| Holographic Overlays | Visual diagnostics | Real-time equipment performance display |

| AR Simulations | Training & planning | Emergency drills and process mapping |

| Spatial Anchoring | Task automation guidance | Assembly line efficiency |

Will Digital Twins Lead to Innovation or Domination?

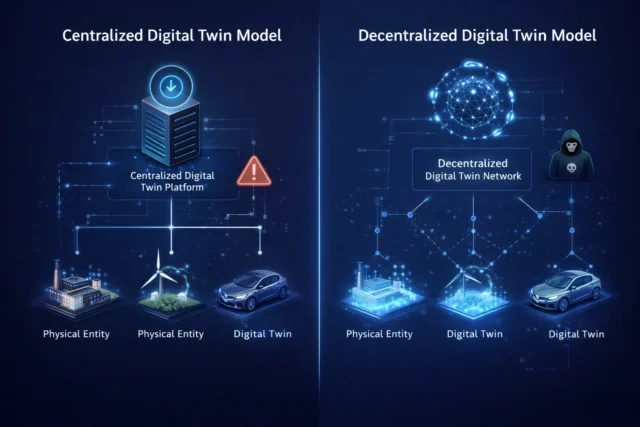

The Corporate Control Question

The danger is the centralization it enables. When a single system holds all operational knowledge, power consolidates. Decision-making shifts upward, away from workers and local managers. This is control! And when coupled with AI-driven recommendations, dissent becomes deviation. Innovation, ironically, may be stifled by too much optimization.

The Counterargument: Empowering Decentralized Intelligence

But digital twins can also decentralize power if designed correctly. By embedding insights across teams, enabling local overrides, and fostering open feedback loops, they can elevate human agency. The same data that enforces compliance can also empower creativity. The key lies not in removing intelligence from the edge but enhancing it.

Control Models in Digital Twin Systems

- Top-down surveillance: Centralized monitoring and enforcement

- Bottom-up empowerment: Worker-led insights and adaptations

- Hybrid models: Central data with distributed decision rights

- Feedback-centric systems: Continuous improvement through user input

In Defense of AI : Why We Must Design, Not Retreat

The future of Industry 4.0 will not be defined by whether we use digital twins, but how we design them. These technologies are not inherently oppressive or liberating, they are mirrors of our intent. Used responsibly, they can optimize operations, improve safety, and empower people. Misused, they become instruments of surveillance, reducing workers to variables in an efficiency equation.

The goal is to push forward intelligently. We must build digital twin systems that are transparent, participatory, and humane. Augmented reality must amplify insight, not enforce conformity. AI must elevate human decision-making, not replace it. Industry 4.0 is not a surveillance dystopia unless we make it one. The tools of innovation are in our hands, it’s time to wield them with wisdom.

The Case for Digital Twins — McKinsey

The Hidden Downside of Automating Workplace Management — Harvard Business Review

Ethical AI and Digital Twins in Industry — World Economic Forum

Is AR the Missing Link in Industry 4.0 or a Futuristic Distraction?